The continuous carbonation process allows reducing production times and increases product quality.

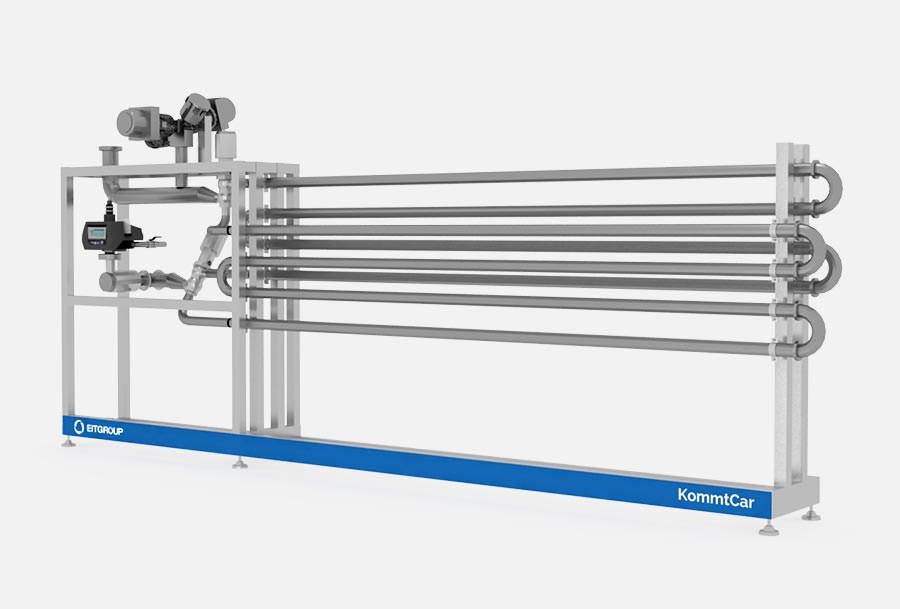

Beverage carbonation uses a continuous dosing system monitored by a CO2 control head provided at the end coil travel. The control link allows regulating the dosage.

The implementation of the system requires few liters of beverage, which is homogenized in the back buffer tank. Having a buffer tank makes the system independent from the one corresponding to the filling of beverages.

The specific design of the static mixer allows for a particular dissolution for each product achieving a homogeneous solution.

With over 10 years of experience, Engineering, Innovation & Technology Group develops as a clear alternative to provide high-level technical advice to companies of different manufacturing and processing industries.